OUR CUSTOMIZED

PROFILES

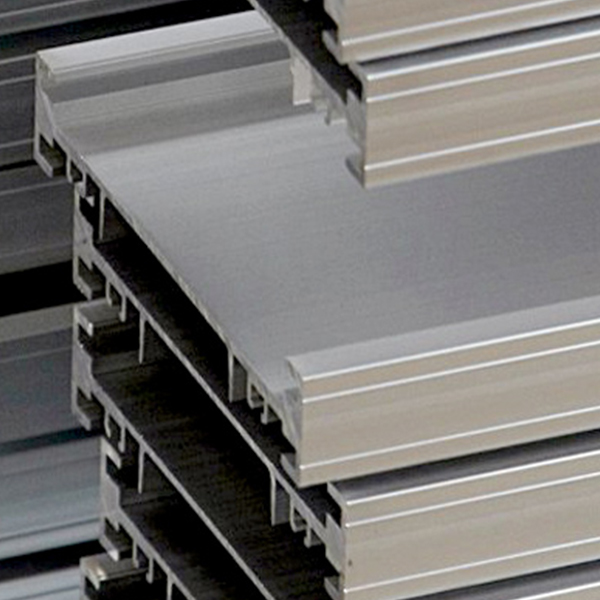

The manufacture of specific profiles represents 70% of Flandria Aluminium’s annual production. This ‘customized experience is a recognized know-how that allows us to make products adapted to the customer’s requirements.

A design office at your service

In order to carry out your customized projects, Flandria provides an advice and technical study stage that goes beyond the simple manufacture of the profile.

We integrate your on-site needs into our analyses: search for multifunctionality, complementary parts, assembly solutions, to ensure you an ideal final operation.

Our technical studies include advice on the choice of alloy (6060, 6005 and 6082) and always lead to producing a “sample profile” before starting the extrusion.

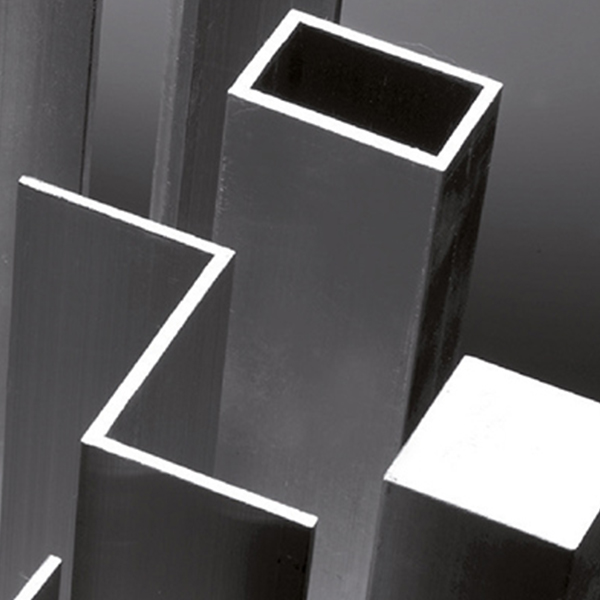

Customized alloys

Building, transport, building systems, industry, decoration, before each project starts our teams bring advice and expertise in the choice of the alloy to carry out your profiles. Flandria carries out the major part of its production in alloys: 6060, 6005 et 6082. Our specialists are able to apply all the heat treatments necessary to improve the mechanical properties of aluminum and thus meet the constraints of many fields of application.

The 6060 alloy offers a good compromise between reliability and mechanical characteristics. Thanks to its high resistance to corrosion, it allows many applications in the building, transport, industrial and decorative building system sectors.

With its high mechanical resistance, the 6005 alloy is ideal for the realization of mechanically stressed elements in the fields of building, shipbuilding and transport. It can also be used for precision micro-mechanics.

The 6082 alloy ensures high mechanical and corrosion resistance. It is easy to form and also offers a very good polishing ability. It offers great adaptability and many options for implementation.

Precision finishes

Depending on your project or need, the profiles may require treatment of surfaces and special finishes. Our specialists perform these for you through lacquering, anodizing in our own machining, assembly and thermal breaking center.

“My job allows me to test the mold in a real extrusion situation and to make the necessary corrections before going into production. I work in close collaboration with the design office and the production workshop; this quality of exchange between the departments is one of Flandria’s strengths.

Sébastien Brillant, Corrector

With this experience of customized products, I am lucky to be able to check new models every day. This diversity in my work is very fulfilling for me.”

Has worked for Flandria for 4 years

Flandria, a trusted partner

Trust is an essential value for us. Each product produced remains the exclusive property of our customers. All our projects are subject to confidentiality and no information is shared outside the company.